There are generally 13 steps to make a makeup brush: weighing – combing – piering – wire tying – tube insertion – measurement – machine dispensing – air drying – trimming – connect handle – cleaning-quality control – packaging-loading

Weighing hair is to make the hair volume more uniform and reduce errors in product production. Because it is handmade, it is difficult to make every brush the same size and bristle shape. However, with the step of weighing the bristle, production errors can be greatly reduced.

Using professional combs to align the bristles for consistency.

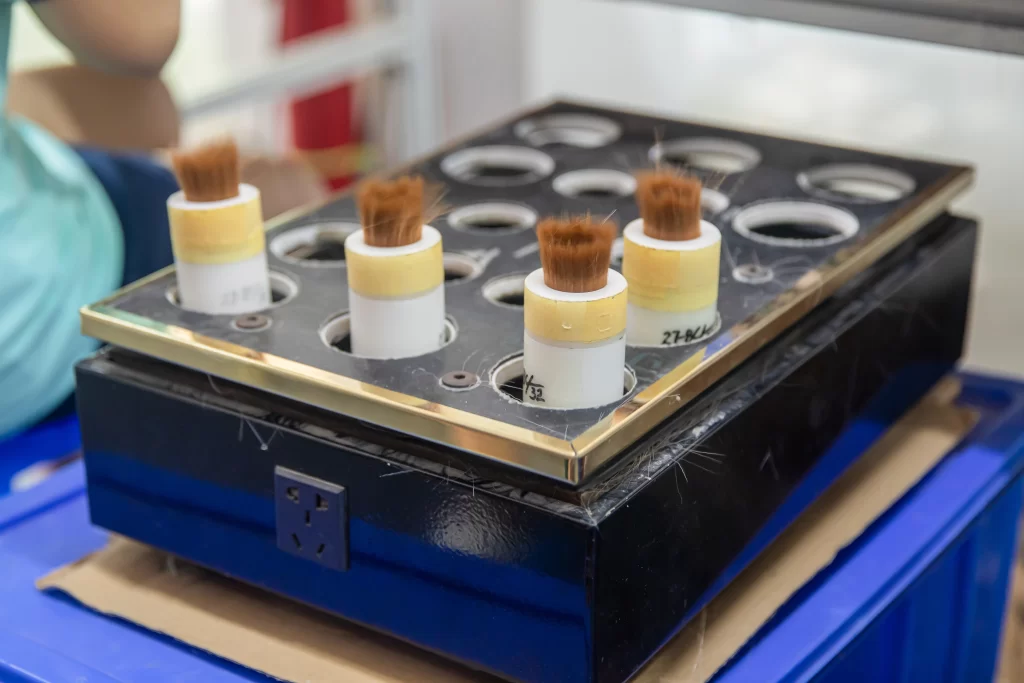

After the bristles are put into the cup, the cup is placed on the jig. The jig can automatically shake the cup to make the bristles inside more uniform and stylish, which not only improves the product quality and reduce labor burden.

Wire tying is to use professional techniques to trap the bristles that have shaken evenly with wires, initially fixing the hair shape and making it easier to enter the tube.

To put into the tube, you put the bundled bristles into the tube. We have also developed a professional pipe entry jig, which can fix the bristles and facilitate workers to insert the mouth pipe into the bristles from top to bottom.

Measurement, this is a very important step. After the bristle head is initially formed, we need to measure the length of the bristle to make this length meet the requirements of our customers. We attach great importance to product quality. You can see our strict control of product quality in all aspects of production.

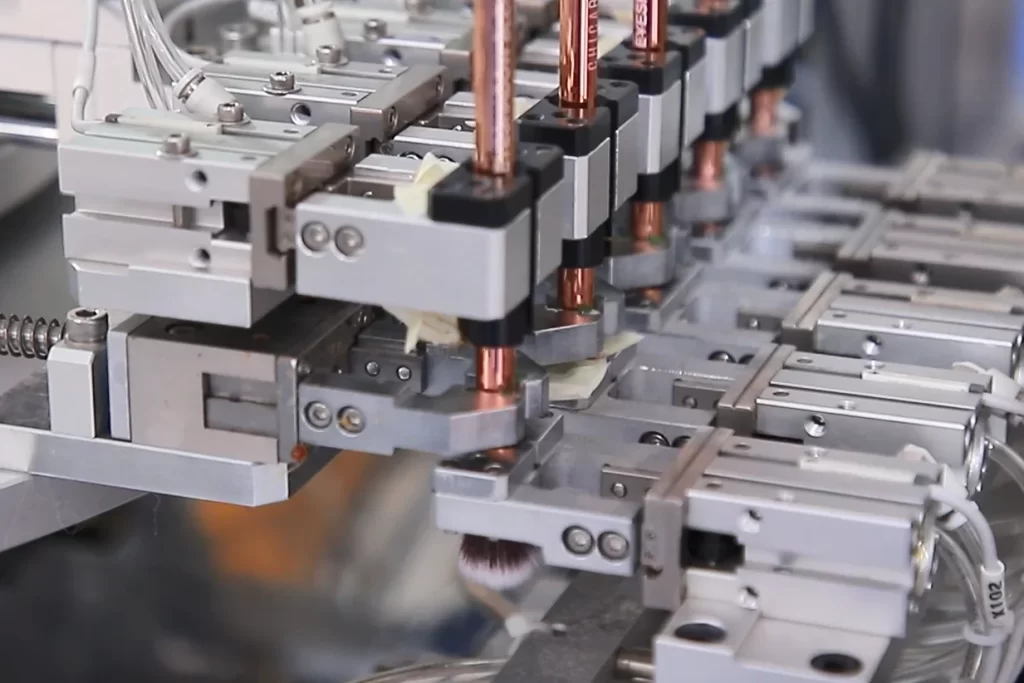

After the machine dispenses glue and the hair head is initially formed, it is necessary to fix the hair head with glue. Other factories all dispense glue manually, but our factory has introduced advanced machinery and equipment. This equipment can make the glue more even and avoid lint loss, which is also a point where we attach great importance to product quality.

Air drying means placing the hair with glue on it in a ventilated place to allow the glue to dry and fix the hair.

Trimming is to use a professional knife to trim the hair into shape, trim off excess bristles, and trim the hair into a more beautiful and rounded shape. You can see that our hair shape is very beautiful. The hair shape we make is very beautiful because we ask a master with more than ten years of experience to make the hair, so it looks very good.

We have fully automatic assembly machine,this machine can solve the problem of mild tilt that cannot be solved manually. In addition, which can prevent hair shedding,effectively preventing the brush head drop.

To clean, use a clean white cotton cloth to clean away excess glue and dirt on the brush.

Each brush undergoes rigorous quality checks.We place great importance on the quality of our products, and each department has established quality inspection procedures.Additionally, we hold weekly production meetings where we emphasize quality issues.

We have specialized pallets and forklifts to reduce manual transportation burden, protect the goods from damage, and facilitate transportation.